We Are the Leading manufacturer & exporter of HyMu® 80 in Salfit, Palestinian Territory Occupied

We manufactures and exports high quality HyMu® 80 in Salfit Palestinian Territory Occupied. Learn more about our products.

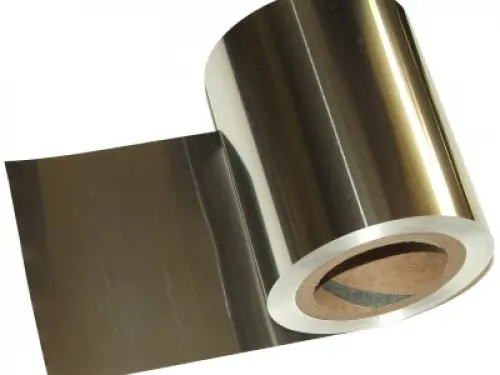

Are you looking for a high-quality and reliable supplier of HyMu® 80 in Salfit, Palestinian Territory Occupied? Look no further! As a leading HyMu® 80 manufacturer, we Metal Fort, take pride in offering a wide range of premium HyMu® 80 products to meet your diverse needs in Salfit, Palestinian Territory Occupied. Our HyMu® 80 is meticulously crafted using state-of-the-art technology and adheres to the highest industry standards, ensuring exceptional durability, corrosion resistance, and longevity. Whether you require HyMu® 80 products, sheets, bars, or fittings, we have you covered. Our experienced team is committed to providing excellent customer service, assisting you in finding the perfect HyMu® 80 solutions for your projects in Salfit, Palestinian Territory Occupied. With our competitive prices and prompt delivery, you can trust us to be your trusted partner for all your stainless steel requirements. Experience the unmatched quality and reliability of our HyMu® 80 products and elevate your projects to new heights. Contact us today and let us be your go-to HyMu® 80 supplier in Salfit, Palestinian Territory Occupied!

We Metal Fort, are leading supplier, manufacturer and exporter of HyMu® 80 in Salfit, Palestinian Territory Occupied area. Get HyMu® 80 in your area now. We delivers our high quality HyMu® 80 products in Salfit, Palestinian Territory Occupied. Take a look on our products that suits your requirements.

Introducing the finest HyMu® 80 products, crafted with precision and durability for Salfit, Palestinian Territory Occupied’s diverse needs. We Metal Fort stands as a trusted leader in HyMu® 80 manufacturing in Salfit, Palestinian Territory Occupied, offering an extensive range of high-quality products that meet the highest industry standards. Whether you're in construction, engineering, or manufacturing, our HyMu® 80 solutions are tailored to elevate your projects to new heights. From corrosion-resistant pipes and fittings to sleek and stylish sheets and bars, we provide the perfect blend of strength, reliability, and aesthetic appeal. Our HyMu® 80 is meticulously crafted, ensuring exceptional performance in even the harshest environments. Partner with us for unmatched expertise, prompt delivery in Salfit, Palestinian Territory Occupied, and competitive prices. Choose the HyMu® 80 experts and experience the difference that quality makes in Salfit, Palestinian Territory Occupied.

HyMu 80 alloy is an unoriented, 80% nickel-iron-molybdenum alloy which offers extremely high initial permeability as well as maximum permeability with minimum hysteresis loss.

Applications

HyMu 80 alloy has been used primarily in transformer cores, tape wound toroids and laminations where compactness and weight factors are important. It has also been used for shielding to protect electrical components from stray magnetic fields.

Corrosion Resistance

This alloy is moderately resistant to moisture and atmospheric corrosion.

Physical Properties

|

Specific gravity ............................ 8.74 |

Electrical resistivity |

Mean Coefficient of Thermal Expansion

|

Test Temparature |

Coefficient |

||

|

°F |

°C |

10(-6)/°F |

10(-6)/°C |

|

-103 to 77 |

-75 to 25 |

6.0 |

10.8 |

|

Curie temperature |

Specific Heat |

Magnetic Properties

|

Coercive Force |

Hysteresis loss |

DC Magnetic Properties

|

Form |

Mu at B = 40 G |

Mu max |

Hc from H = 1 Oersted |

|

Bar, Wire |

50,000 |

200,000 |

0.02 max |

|

DC Hysteresis loss |

Residual Induction, gauss |

AC Magnetic Properties, 60 Hz

Minimum limits

|

Thickness |

Mu 40 G |

Mu 200 G |

Mu 2000 G |

|

|

Inches |

Millimeters |

|||

|

0.025(1) |

0.635 |

35,000 |

40,000 |

55,000 |

Heat Treatment

In-process anneal

To relieve all strains and restore the alloy to a soft condition suitable for drawing, spinning, forming, bending or similar operations, anneal at 1450/1850°F (788/1010°C) for not more than 1 hour. Since the high nickel, high permeability alloys readily absorb carbon, sulfur, oxygen and other contaminants from combustion furnace gasses, in-process annealing should be conducted in dissociated ammonia, hydrogen, vacuum or inert gas atmospheres.

Hydrogen anneal

For maximum softness and optimum magnetic and electrical properties, HyMu 80 alloy should be annealed in an oxygen-free, dry hydrogen atmosphere with a dew point below -40°F at 2050/2150°F for 2 to 4 hours. Furnace cool to 1100°F. From 1100 to 700°F, cool at rate between 350 to 600°F per hour.

Oil, grease, lacquer and all other contaminants must be removed before annealing. The individual parts should be seperated by an inert insulating powder such as magnesium and aluminum oxide during hydrogen annealing.

Vacuum heat treating can be employed. Generally, there is some small sacrifice in magnetic properties compared to heat treating in a dry hydrogen atmosphere.

Machining

The following chart reports data compiled from various machining operations performed on HyMu 80 alloy using the high-speed tool materials indicated. When using carbide tools, double the sf/m shown in the chart.

|

Operation |

Speed |

Feed |

Tool |

||

|

sf/m |

m/s |

l/r |

mm/r |

||

|

Turning |

50 |

0.254 |

0.0007/0.002 |

0.018/0.051 |

M42 |

Figures used for all metal removal operations covered are average. On certain work, the nature of the part may require adjustment of the speeds and feeds. Each job has to be developed for best production results with optimum tool life. Speeds and feeds should be increased or decreased in small steps.

HyMu 80 alloy machines somewhat like the austenitic stainless alloys but doesn't work harden as rapidly. Gummy chips develop in most machining operations. Work hardened bars (Rockwell B 90 minimum) offer the best machining characteristics.

Lard oil should be used for drilling and machining operations which must be done at slow speeds. If sulfur-bearing and water-soluble cutting compounds are used, the parts should be thoroughly cleaned within 48 hours, then heat treated. High speed steel or carbide tools are suggested for cutting operations.

Cold forming

For best blanking characteristics, HyMu 80 alloy strip should be ordered in the cold rolled condition (Rockwell B 90 minimum). For best forming characteristics, strip should be ordered in the cold rolled and annealed condition. For best drawing characteristics, strip orders should be endorsed "annealed, deep draw quality".

Welding

HyMu 80 alloy is readily welded by following the usual pracitices for ferrous alloys. If a filler metal is required, use the same analysis. Finish annealed parts can be soft or hard soldered. Do not braze or solder prior to final heat treatment.

Shielding Properties

Because of its very high permeability and very low coercive force, HyMu 80 alloy is particularly well suited for magnetic shielding applications.

Annealed, deep draw quality strip can be fabricated into shields by bending, drawing and spinning. Where joining is required, spot welding or tungsten inert-gas welding can be used, with or without a base metal filler rod.

To develop the best shielding characteristics, shields must be annealed at 1900°F or higher (as described in the heat treatment section) after all fabricating operations have been completed. In general, higher annealing temperatures yield higher permeability and better shielding characteristics.

To determine its relative shielding capability, a material is evaluated as an open-ended cylindrical shield in a uniform magnetic field, such as that produced by a Helmholtz coil. When a pickup unit is centered in the field of the coil, the attenuation (A) is the ratio of the reading with no shield (E1)to that obtained when a shield is positioned over the pickup (E2), with its axis perpendicular to the field (A=E1/E2).

This is a measure of the shielding effectiveness under the particular test conditions, and for a given material depends upon the shield thickness, its length-to-diameter ratio and the diameter of the Helmholzt coil.

Typical Mechanical Properties

Bar

|

Tensile |

Yield |

Proportional |

% |

% |

Hardness |

|||

|

ksi |

MPa |

ksi |

MPa |

ksi |

MPa |

|||

|

---------------------------------As Cold Drawn---------------------------------- |

||||||||

|

97 |

669 |

69 |

414 |

19 |

131 |

37 |

71 |

97 |

|

----------------As Hydrogen Annealed at 2050°F(1121°C)----------------- |

||||||||

|

79 |

545 |

22 |

152 |

19 |

131 |

64 |

70 |

62 |

|

------------------After Process Anneal at 1600°F(871°C)------------------- |

||||||||

|

90 |

620 |

33 |

228 |

28 |

193 |

57 |

74 |

85 |

|

Modulus of Elasticity |

Izod Impact |

||

|

10(3)ksi |

10(6)MPa |

ft-lb |

J |

|

---------------------------------As Cold Drawn---------------------------------- |

|||

|

33.7 |

232 |

120 |

163 |

|

----------------As Hydrogen Annealed at 2050°F(1121°C)----------------- |

|||

|

33.3 |

230 |

85 |

115 |

|

------------------After Process Anneal at 1600°F(871°C)------------------- |

|||

|

31.4 |

217 |

85 |

115 |

Strip

|

Tensile |

Yield |

Proportional |

% |

Hardness |

|||

|

ksi |

MPa |

ksi |

MPa |

ksi |

MPa |

||

|

---------------------------------As Cold Rolled---------------------------------- |

|||||||

|

135 |

931 |

-- |

-- |

-- |

-- |

4 |

100 |

|

----------------As Hydrogen Annealed at 2050°F(1121°C)----------------- |

|||||||

|

77 |

531 |

21 |

145 |

15 |

103 |

38 |

58 |

|

------------------After Process Anneal at 1600°F(871°C)------------------- |

|||||||

|

98 |

676 |

38 |

262 |

35 |

241 |

38 |

85 |

Application Specifications

HyMu 80 alloy meets military specification Mil-N-14411 B and ASTM-A-753-78 standard specification.

Product Ratings & Reviews

Finnley Wolf

1 year ago

Hamish Gillespie

Thanks

1 year ago

Jenson Marsh

Best HyMu® 80 in Mumbai

1 year ago

Karina Craig

Best for commercial metals.

1 year ago

Maison Hampton

1 year ago

Caitlyn Zimmerman

1 year ago

Timothy Galvan

Thanks

1 year ago

Christopher Byrd

1 year ago

Philippa Mclean

1 year ago

Sydney Mcconnell

1 year ago

Dasra Devadhikar

The best quality HyMu® 80 in my area

1 year ago

Awais Connor

1 year ago

Karina Blake

Best quality, no delays

1 year ago

Jessie Chapman

The best

1 year ago

Natalia Arnold

Best HyMu® 80 in Mumbai

1 year ago

Callum Mcdowell

The best quality HyMu® 80 in my area

1 year ago

Harley Conner

1 year ago

Callie Carpenter

Good products

1 year ago

Ruth Serrano

1 year ago

Ashleigh Hunter

Thanks

2 years ago

Eden Rhodes

Best for commercial metals.

2 years ago

Suzanne Evans

Ordered for my project and got best quality HyMu® 80. Thany you.

2 years ago

Theo Shepard

2 years ago

Aarav Davidson

2 years ago

Jamadagni Ajagavakar

2 years ago

Mikayla Lawson

Ordered for my project and got best quality HyMu® 80. Thany you.

2 years ago

Ashleigh Hunter

World class HyMu® 80.

2 years ago

Zoe Leblanc

Best for commercial metals.

2 years ago

Reuben Walters

2 years ago

Baibhav Kamal

The best

2 years ago

Alistair Reynolds

2 years ago

Dalton Reeves

Best quality, no delays

2 years ago

Tiffany Gregory

The best

2 years ago

Marley Curtis

Good products

2 years ago

Alistair Tran

Thanks

2 years ago

Emily Ballard

2 years ago

Devon Collier

2 years ago

Selina Hayden

2 years ago

Darcie Cisneros

2 years ago

Humza Woods

Best HyMu® 80 in Mumbai

2 years ago

Kenneth Gutierrez

2 years ago

Mya Hamilton

2 years ago

Amaan Martinez

2 years ago

Jensen Mullen

2 years ago

Eden Rhodes

2 years ago

Irene Bennett

3 years ago

Shawn Camacho

3 years ago

Jayson Kim

Ordered for my project and got best quality HyMu® 80. Thany you.

3 years ago

Tobias Mckenzie

3 years ago

Cormac Berg

3 years ago

Nancy Williamson

Good products

3 years ago

Demi Ray

Good products

3 years ago

Kelly Bloggs

Thanks

3 years ago

Ruldu Panda

3 years ago

Sulayman Eaton

3 years ago

Abbey Larsen

Best quality, no delays

3 years ago

Trystan Daugherty

The best

3 years ago

Ragunath Havaldar

Thank You very much!!!

3 years ago

Molly Waller

3 years ago

Jamil Clayton

Ordered for my project and got best quality HyMu® 80. Thany you.

3 years ago

Chander Sinha

3 years ago

Brooklyn Shaw

3 years ago

Karina Blake

3 years ago

Arpit Karamchand

3 years ago

Troy Byrne

3 years ago

Mae Flynn

Its a great product, thank you!!!

3 years ago

Caoimhe Bender

3 years ago

Lee Castillo

3 years ago

Hannah Harvey

Thanks

3 years ago

Cheryl Woods

Thanks

3 years ago

Ava Baxter

Best HyMu® 80 in Mumbai

3 years ago

Evie Watson

3 years ago

Deacon Cuevas

3 years ago

Lulu Hood

Its a great product, thank you!!!

4 years ago

Xander Hensley

4 years ago

Pari Mallaya

4 years ago

Zuzanna Walsh

4 years ago

Dawid Parrish

The best quality HyMu® 80 in my area

4 years ago

Yasmine Henry

Thanks

4 years ago

Tessa Gardner

World class HyMu® 80.

4 years ago

Axel Briggs

4 years ago

Zachary Andersen

4 years ago

Susannah Gentry

4 years ago

Maisie Yang

4 years ago

Kyra Harding

Best for commercial metals.

4 years ago

Sally Schneider

The best

4 years ago

Frazer Sherman

Its a great product, thank you!!!

4 years ago

Danny Stewart

4 years ago

Tahlia Morton

4 years ago

Susannah Gentry

4 years ago

Hamish Gillespie

4 years ago

Sofia Reynolds

4 years ago

Jerome Hill

Good products

4 years ago

Otis Roberson

4 years ago

Rafe Page

4 years ago

Lilia Young

Good products

4 years ago

Ambika Bakshi

4 years ago

Aaron Espinoza

Best HyMu® 80 in Mumbai

4 years ago

Keira Glass

4 years ago

Effie Brennan

4 years ago

Fay Day

4 years ago

Evie Watson

Good products

4 years ago

Dominik Goodwin

Its a great product, thank you!!!

5 years ago

Zahraa Wilkins

The best quality HyMu® 80 in my area

5 years ago

Emilio Terrell

5 years ago

Maha Shevade

5 years ago

Harley Reyes

Thank You very much!!!

5 years ago

Jerome Hill

5 years ago

Ayah O'Gallagher

The best

5 years ago

Louie Hubbard

5 years ago

Remi Harper

Thanks

5 years ago

Pamela Mahoney

Good products

5 years ago

Adam Kaufman

Thanks

5 years ago

Andreas Butler

The best quality HyMu® 80 in my area

5 years ago

Dharya Sirasikar

Thank You very much!!!

5 years ago

Lee Castillo

5 years ago

Henri Vincent

5 years ago

Eliot Vaughan

5 years ago

Keenan Williams

Thank You very much!!!

5 years ago

Inaaya Garza

5 years ago

Ragunath Havaldar

6 years ago

Chettur Devdhar

World class HyMu® 80.

6 years ago

Howard Wagner

6 years ago

Dora Norris

Thanks

6 years ago

Otis Roberson

Its a great product, thank you!!!

6 years ago

Shankaracharya Poddar

Best for commercial metals.

6 years ago

Jermaine Cantu

6 years ago

Fraser Chavez

Ordered for my project and got best quality HyMu® 80. Thany you.

6 years ago

Omar Pitts

World class HyMu® 80.

6 years ago

Idris Andrews

6 years ago

Lillie Hernandez

6 years ago

Zayn Ayers

The best quality HyMu® 80 in my area

6 years ago

Jorja Larson

6 years ago

Tony Ramirez

6 years ago

Charlotte Horne

6 years ago

Timothy Galvan

6 years ago

Jaime Young

Its a great product, thank you!!!

6 years ago

Sydney Mcconnell

Best for commercial metals.

6 years ago

Tara Haney

6 years ago

Zayn Ayers

6 years ago

Vaidehi Nan

6 years ago

Jeremy Benton

Thanks

6 years ago

Roisin Jefferson

6 years ago

Haris Graves

6 years ago

Jacqueline Beltran

6 years ago

Jermaine Cantu

7 years ago

Saarah Houston

7 years ago

Kyle Carroll

7 years ago

Adelaide Gay

7 years ago

Michelle Vincent

7 years ago